A team of researchers at the University of California San Diego has made significant advances in solving some of the most vexing challenges in bioprinting 3D-engineered tissues while meeting the key requirements of high cell density, high cell viability and fine fabrication resolution.

The research led by nanoengineers at the UC San Diego Jacobs School of Engineering was published in the February 22, 2023 issue of Science Advances.

Bioprinting is based on 3D-printing technology, using cells and biopolymer to create biological structures and tissues. 3D-engineered tissues—lab-created yet functional human-like tissues made of living cells and biomaterial scaffolds—have great potential for biomedical applications, including drug testing and development, organ transplants, regenerative medicine, personalized medicine, disease modeling, and more. Their uses could add significant speed and integrity to the process of drug development, as well as helping to mitigate challenges associated with organ-donor shortage and immune rejection.

One of the most promising types of 3D-bioprinting is called digital light processing (DLP) bioprinting. Within this branch of 3D-bioprinting, progress has been impeded by practical and technical impediments. It has proven difficult to print tissues with high cell densities and finely resolved structures.

“After printing, we culture the construct to allow the cells to mature or reorganize into a functional tissue. Therefore, the cell is like a seed, and each cell type has a specific density at which they are most potent to sprout,” said Shaochen Chen, the nanoengineering professor leading the research team.

Using existing approaches, the more dense the presence of cells in bioink, which is a biocompatible polymer used in DLP-based 3D bioprinting, the more the light scatters, hindering printing resolution.

The researchers reduced this light-scattering effect tenfold, allowing them to print with high cell densities and high resolution thanks to the contrast agent iodixanol, a new ingredient in the bioink.

“Using iodixanol, we developed a refractive index-matched bioink for DLP-based bioprinting to mitigate the light scattering of the cells, concentrating the energy within the user-defined light pattern to improve the printing fidelity,” said Shangting You, a nanoengineering postdoc fellow at UC San Diego, member of Chen’s team and co-first author of the research paper.

For nearly two decades, Chen’s lab has helped steer in the development of DLP-based 3D printing and bioprinting techniques, helping create the foundation for modern 3D biomanufacturing.

How it works

DLP-based 3D bioprinting uses a digital micromirror device (DMD) to project a 2D cross-section of the 3D model to the photo-crosslinkable bioink. When exposed to light, the photocrosslinkable bioink, which can be either synthetic or natural, solidifies. Then, a motorized stage lifts up the bioink by a few tens microns to 200 microns, which allows uncured bioink to refill the gap. When the next cross-section is projected to the bioink, a new layer solidifies and the process repeats.

When all goes well, a newly formed layer precisely matches the shape of the projected cross-section. However, with existing methods, the incorporation of cells in the bioink can cause severe light scattering, which blurs the projected light in the bioink. As a result, the newly formed layers cannot replicate the fine details of the projected cross-sections.

Tuning the refractive index of the bioink minimizes this scattering effect and significantly improves the fabrication. The Chen Lab’s research shows that a ~50 µm feature size can be achieved in a refractive-index-matched gelatin methacrylate (GelMA) bioink with a cell density as high as 0.1 billion/mL.

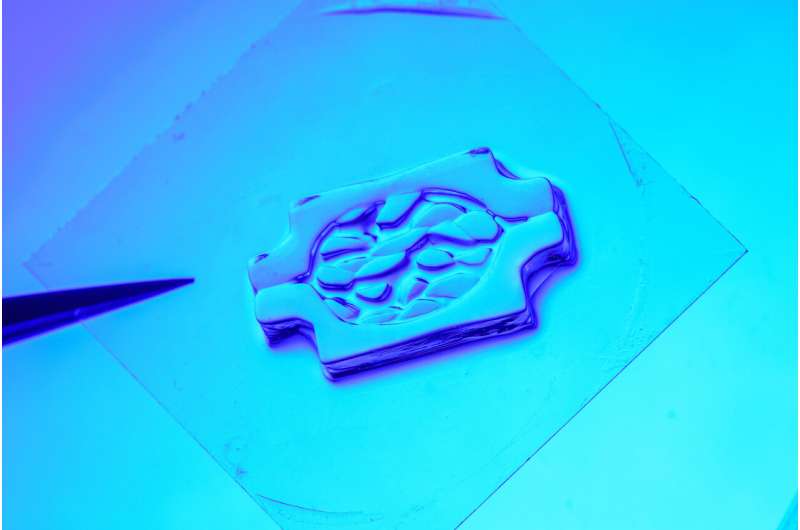

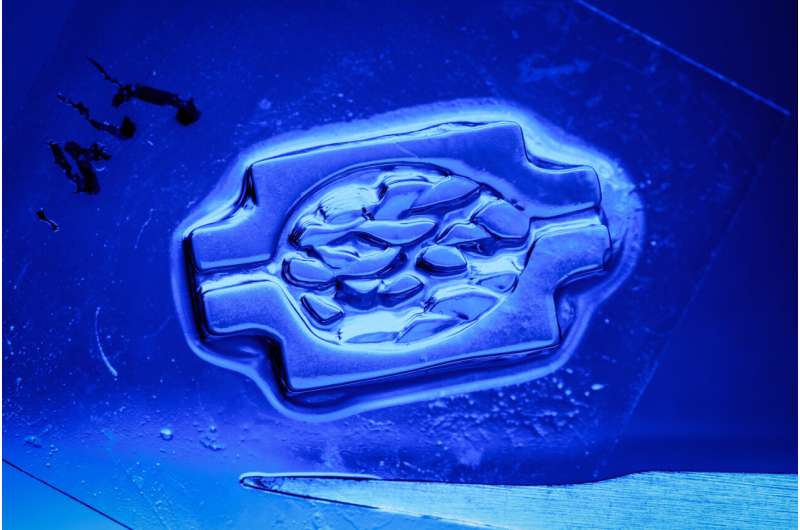

This approach introduces a few novel technical innovations, including a hollow organic vascular network embedded in a cell-laden thick tissue, enabling it for perfused and long-term culture, and a snowflake and spoke shape to showcase the high resolution for both positive and negative features.

The project was not without its challenges. “We have developed various bioink materials and several protocols for handling them,” said Yi Xiang, a nanoengineering Ph.D. student at UC San Diego, member of Chen’s team and co-first author of the research paper. “But with the longer printing time for a larger tissue, any inconsistency and instability in the cells and in the biomaterial was amplified. Therefore, we had to modify and optimize both the material composition and the handling procedures.”

This project marks the first use of iodixanol as a bioink in DLP bioprinting, at a high cell density and with long intervals of exposure. “We performed a series of biological investigations to evaluate this impact and developed some post-printing procedures to sufficiently dissipate the iodixanol,” Xiang said.

With the improved printing resolution mediated by iodixanol, a high cell-density, pre-vascularized tissue with an overall size of 17 x 11 x 3.6 mm3 was fabricated.

“In vitro culture of such a thick tissue has been hindered by the limited diffusion of oxygen and nutrients,” Chen said. “We were able to print perfusable vascular lumens embedded in the tissue with diameters ranging from 250 µm to 600 µm, which was interfaced with a perfusion system for long-term culture. We demonstrated that the vascular lumens were endothelialized, and the thick tissue remained viable for 14 days of culture.”

Next steps

The team continues to work on optimizing its materials system and bioprinting parameters for functional thick tissue fabrication and has filed a provisional patent covering this work.

Further next steps Chen suggests include developing precisely structured, high cell-density in vitro tissue models for improved histological and functional recapitulation, with an eye toward high cell-density large-tissue printing for tissue and organ transplants and replacements in human subjects.

More information:

Shangting You et al, High cell density and high-resolution 3D bioprinting for fabricating vascularized tissues, Science Advances (2023). DOI: 10.1126/sciadv.ade7923

Journal information:

Science Advances

Source: Read Full Article